Search This Supplers Products:Conveyors and Conveyor componentsplastic chains,plastic modular belts,plastic componentsspiral conveyorsconveyor system

Major project of CNC machine tools "Projects for Flexible, Agile, High-Efficiency, Precision, and Automatic Production Line Demonstration Engineering for Automobile Crankshaft"

publishergzhj

time2018/04/27

- Recently, the "National Top Grade High-tech Numerical Control Machine Tools and Basic Manufacturing Equipment" national science and technology major project (hereinafter referred to as "CNC machine special project") "Automobile crankshaft processing flexible, agile, efficient, precise, automated production line demonstration project" successfully passed the task acceptance.

Recently, the "National Top Grade High-tech Numerical Control Machine Tools and Basic Manufacturing Equipment" national science and technology major project (hereinafter referred to as "CNC machine special project") "Automobile crankshaft processing flexible, agile, efficient, precise, automated production line demonstration project" successfully passed the task acceptance.

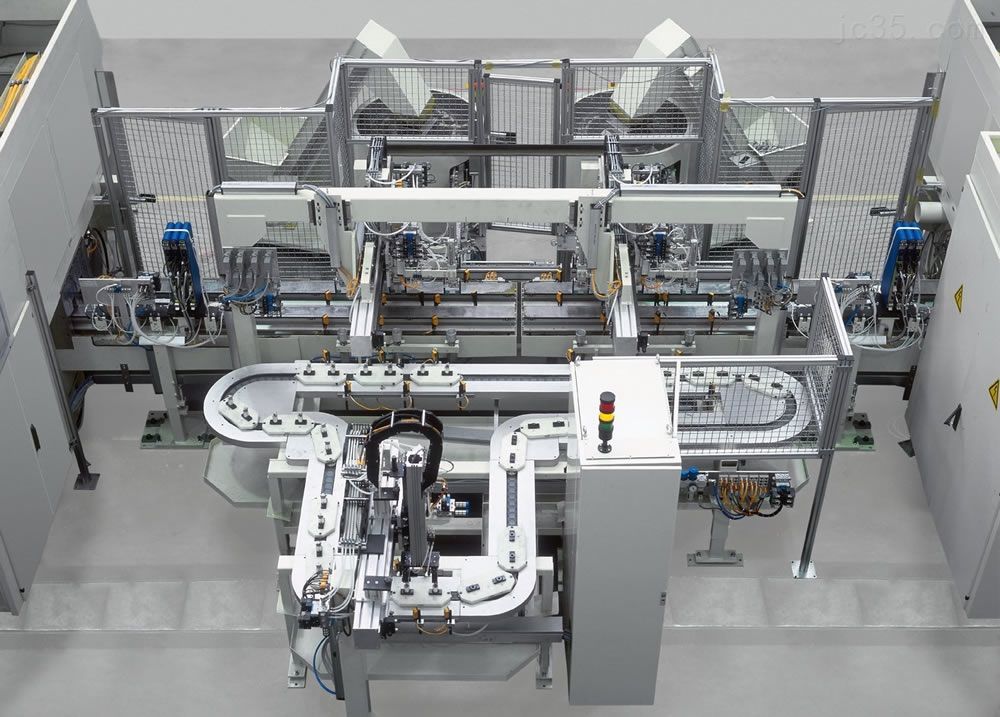

The project was completed and put into production of a car crankshaft production line, which significantly increased production capacity and effectively saved production costs and human resource costs. The results of the project have further enhanced reliability through demonstration applications. The indexes of the double-grinding wheel follower crankshaft grinder have reached the international advanced level and are applied to a number of crankshaft production enterprises; the crankshaft finishing complete sets of equipment support some domestic market demands. From 2015 to 2017, the project achievements and derivative incubation products achieved an average annual sales income of 160 million yuan in some enterprises. Through integrated innovation, we have provided customers with more choices, promoted market competition, and saved more than 320 million yuan in purchase costs for users.

The project takes the lead in assuming that the production line with special support for CNC machine tools will be used as a demonstration, and four new crankshaft automated processing conveying equipment lines will be successively built. At the same time, the equipment manufacturers within the United Nations have formed the ability to provide complete production line construction solutions and have achieved sales of three production lines. Through the research and development of the project, the technical level and competitiveness of the automotive crankshaft manufacturing equipment have been effectively improved, supporting the improvement of the quality of the industry and the transformation and upgrading of the manufacturing model.