Search This Supplers Products:Conveyors and Conveyor componentsplastic chains,plastic modular belts,plastic componentsspiral conveyorsconveyor system

Four major risks in China's small and medium-sized stainless steel mesh belt enterprises

publisherGuangzhou Hongjiang

time2018/11/26

- Four major risks in China's small and medium-sized stainless steel mesh belt enterprises

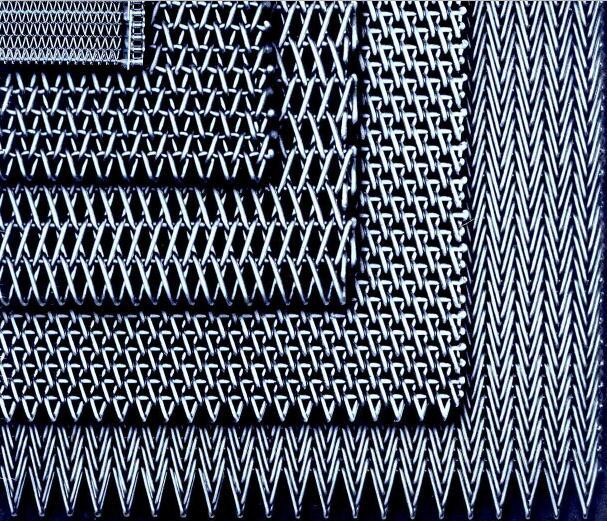

In recent years, with the rapid development of China's food and beverage industry, the stainless steel mesh belt industry with its support has also developed rapidly with strong momentum. However, although the market demand for this product is large, due to the large number of repeated production in the same region, low technical level, poor product quality, etc., the profit margin of enterprises is small, especially for SMEs in the low-price competition. The current product level of China's stainless steel mesh belt manufacturing industry is pagoda-like. At the bottom is a large number of low-level repetitive products. There are fewer high-end products. The data shows that there are nearly 3,000 stainless steel mesh belt manufacturers in the country, of which more than 1,000 are not stable enough, and nearly 15% of enterprises change or close down each year. There are only a dozen enterprises with output value and sales exceeding 100 million yuan, and only 40 enterprises with annual sales exceeding 50 million yuan. 65% of the export products in the industry are produced by these 50 enterprises. The industry believes that the reshuffle of the industry is inevitable, and small businesses will be phased out and merged in the competition. There are many reasons for this situation, including the following four aspects:

1. The variety of stainless steel mesh belt products and the number of complete sets are small. Most of the domestic production is dominated by single machines, while most of the foreign countries are supporting production and rarely sell in a single machine. On the one hand, the varieties of domestically produced equipment cannot meet the needs of domestic network belt and network chain enterprises. On the other hand, the profit of single-machine production and sales of machinery factories is meager, and the high efficiency of complete equipment sales cannot be obtained.

2. The technical level of stainless steel mesh belt is low. The main performance is poor product reliability, slow technology update, and less application of new technologies, new processes and new materials. China's network belts and network chains have more single machines, fewer sets, more general-purpose models, and fewer equipments that meet special requirements and special materials. There are many products with low technical content, and there are few products with high technology added value and high productivity. Intelligent equipment is still in the development stage. Foreign countries have applied many advanced technologies to packaging machinery, such as remote remote control technology (including monitoring), stepper motor technology, automatic flexible compensation technology, laser cutting technology, and information processing technology.

3, stainless steel mesh belt products are of poor quality. The quality gap between China's network belt and network chain products is mainly reflected in poor stability and reliability, backward shape, rough appearance, short life of basic parts and components, short fault-free operation time, short overhaul period, and most products are not yet available. Develop reliability standards. The international packaging industry attaches great importance to improving the general capabilities of packaging machinery processing and the entire packaging system. Therefore, the professionalization of packaging machinery parts production is an inevitable trend of development. Many parts are no longer produced by packaging machinery factories, but by some common standard parts. Factory production, some special parts are produced by highly specialized manufacturers, and the truly famous packaging machinery factory will probably be the assembly plant. Stainless steel mesh belt products are developing towards multi-function and single, high-speed polarization. The ultimate role of packaging machinery is to improve production efficiency and product diversification.

4. Insufficient development capability of stainless steel mesh belt. China's network belt and network chain are mainly imitation, mapping, and a little localization improvement, can not talk about development research. Product development lacks innovation and is difficult to level. Production methods are lagging behind, and most of them are processed with old general equipment. New product development is not only small, but also has a long development cycle. In enterprise management, production, light research and development, and innovation are often insufficient, and products cannot be provided in a timely manner in line with market demand.